NEXUS

Screw-less Hairdryer designed for disassembly

Timeline

5 weeks

Tools

Sketching

Prototyping

Solidworks

3D Printing

Keyshot

Product Description

Nexus is a screw-less, single-material hairdryer designed to make electronics easier to understand, repair, and keep in use. Its single material housing and color-coded internal components turn disassembly into a clear, hands-on process, inviting users to open, maintain, and reassemble the product without special tools. By making repair straightforward and repeatable rather than intimidating or inaccessible, Nexus encourages users to extend product life, reduce e-waste, and build a more confident, informed relationship with their everyday tech.

Challenge

How Might We Reduce Fear Around Electronics and Make Repair Trendy?

60%

60% of consumers discard their electronics when minor issues arise rather than attempt repair.

50

million metric tons

50 million metric tons of electronic waste are produced globally each year.

20%

Only 20% of the global electronic waste is recycled properly.

70%

E-waste contributes 70% of toxic waste in landfills.

Product Features

Reduced Material Usage: Nexus redefines sustainability with its innovative single-material housing, eliminating the need for screws. Components seamlessly connect using tabs and threads, reducing material waste while ensuring a sleek and durable design. This approach simplifies assembly and recycling, aligning with Nexus's commitment to eco-friendly innovation.

Design for Disassembly: Nexus rethinks traditional design by prioritizing easy disassembly. Each component is thoughtfully engineered to be separated effortlessly, using intuitive tabs and threads instead of complex fasteners. This approach encourages repairability, extends product life, and simplifies recycling, making sustainability an integral part of its design philosophy.

Simplifying Electronics with Color-Coding: Nexus redefines accessibility in electronics with intuitive color-coding, allowing users to easily identify and distinguish parts without relying on technical terms. This reduces the fear often associated with electronics while promoting confidence in repair and maintenance. Additionally, Nexus features significantly fewer mixed-material components compared to the Conair hairdryer, further simplifying the recycling process by enabling materials to be easily separated before drop-off. This thoughtful design ensures a user-friendly and sustainable experience.

Process

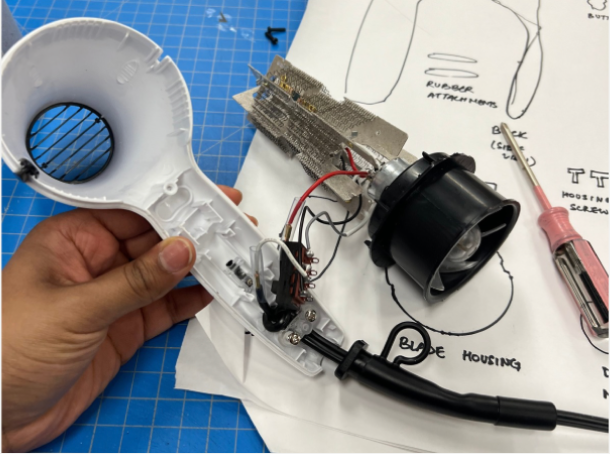

Studying a Hairdryer

I disassembled a Conair hairdryer to analyze its construction, revealing components such as a plastic housing, DC motor, heating element, mica sheet insulator, and plastic air vents. This breakdown offered key insights into its material composition and repair potential.

Screws

Buttons

Tabs

Buttons

Metal Mesh

Electronics

Understanding the materials used

I color-coded the parts of the hairdryer into material groups: mixed materials (blue), plastic (purple), metal (orange), mica sheets (green), and silicone (red). This helped identify the variety of materials used and their roles in the design, offering insights into opportunities for improved recycling and repairability.

Solutions

1.

Reducing Parts with Mixed Materials

Making the housing of the hairdryer out of plastic and omit the use of screws and other materials.

2.

Make things easier to take apart

Changing connection and connectors to ensure that the parts of a hairdryer are easy to take apart.

3.

Make electrical components easier to identify

Using color as the identifying factor to differentiate between electrical components.

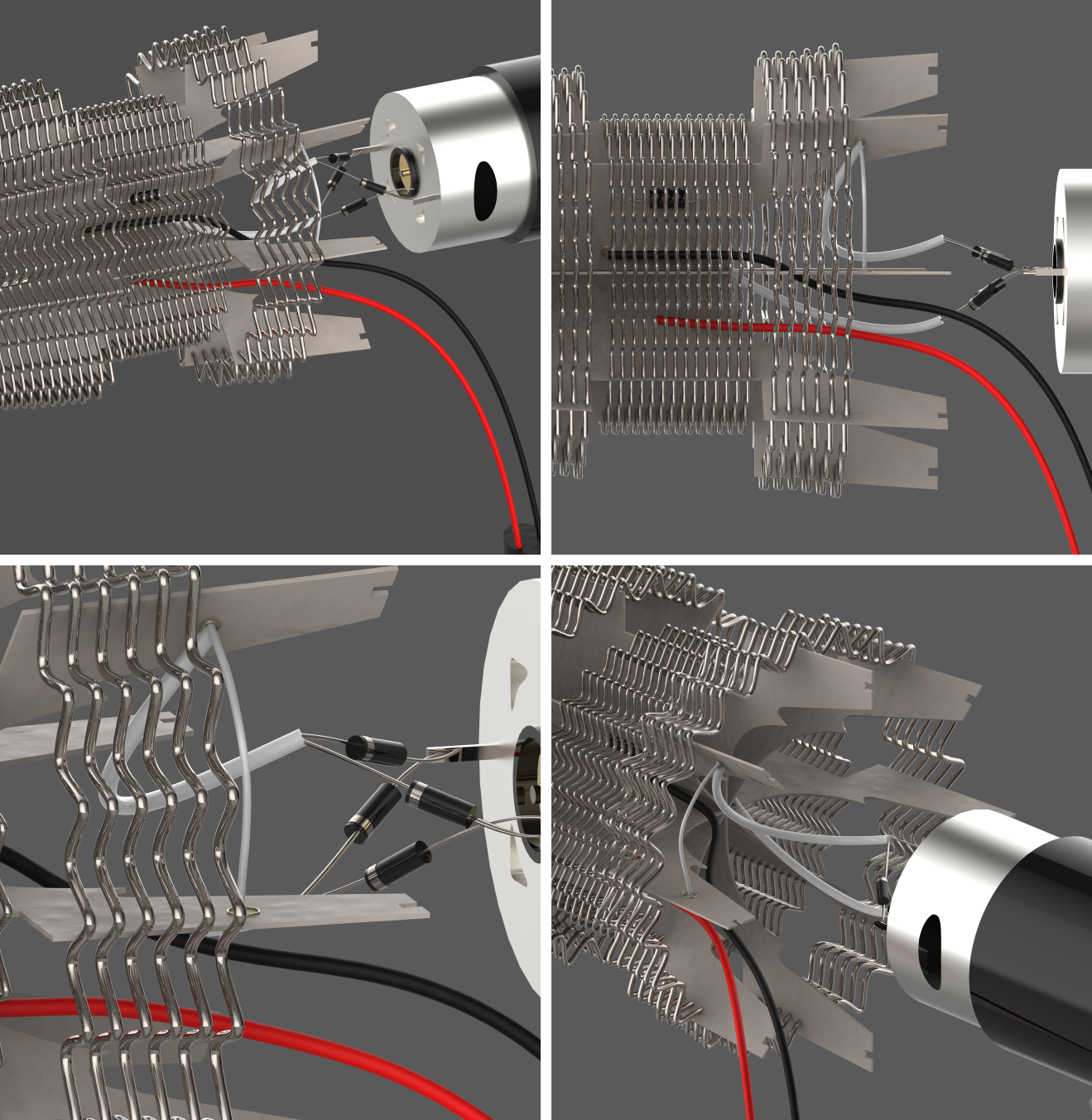

Prototyping

Housing

Take apart/Break down

Exploring various methods for the hairdryer housing to be easily assembled and disassembled, focusing on simplifying repairability and enhancing user interaction.

Attachments

Adopting more familiar ways to connect parts

Using thread and twist mechanisms with parts made of the same material to see how easy they are to take apart and put back together.

Attachments

I conducted tolerance and fit testing to ensure the hairdryer components align and function properly. I tested the tab fit to see how well the housing parts came together, ensuring there were no gaps or excessive tightness. I also tested how the electrical components fit inside the housing, checking for proper alignment and secure placement. These tests helped me refine the design for better functionality and ease of assembly.

Testing tab fit

Test the fit of electrical components

Working Prototype

Nexus rendered