FLEXFLOW

IV Stopcock Reimagined

Timeline

3 months

Tools

Sketching

Prototyping

Solidworks

3D Printing

Keyshot

User Testing

Team

Amy Vu

Andrew Willwerth

Emma Hagenaars

Valentina Grether

Katherine Sheire

Sree Garudadri

Mridvika Shah

Product Description

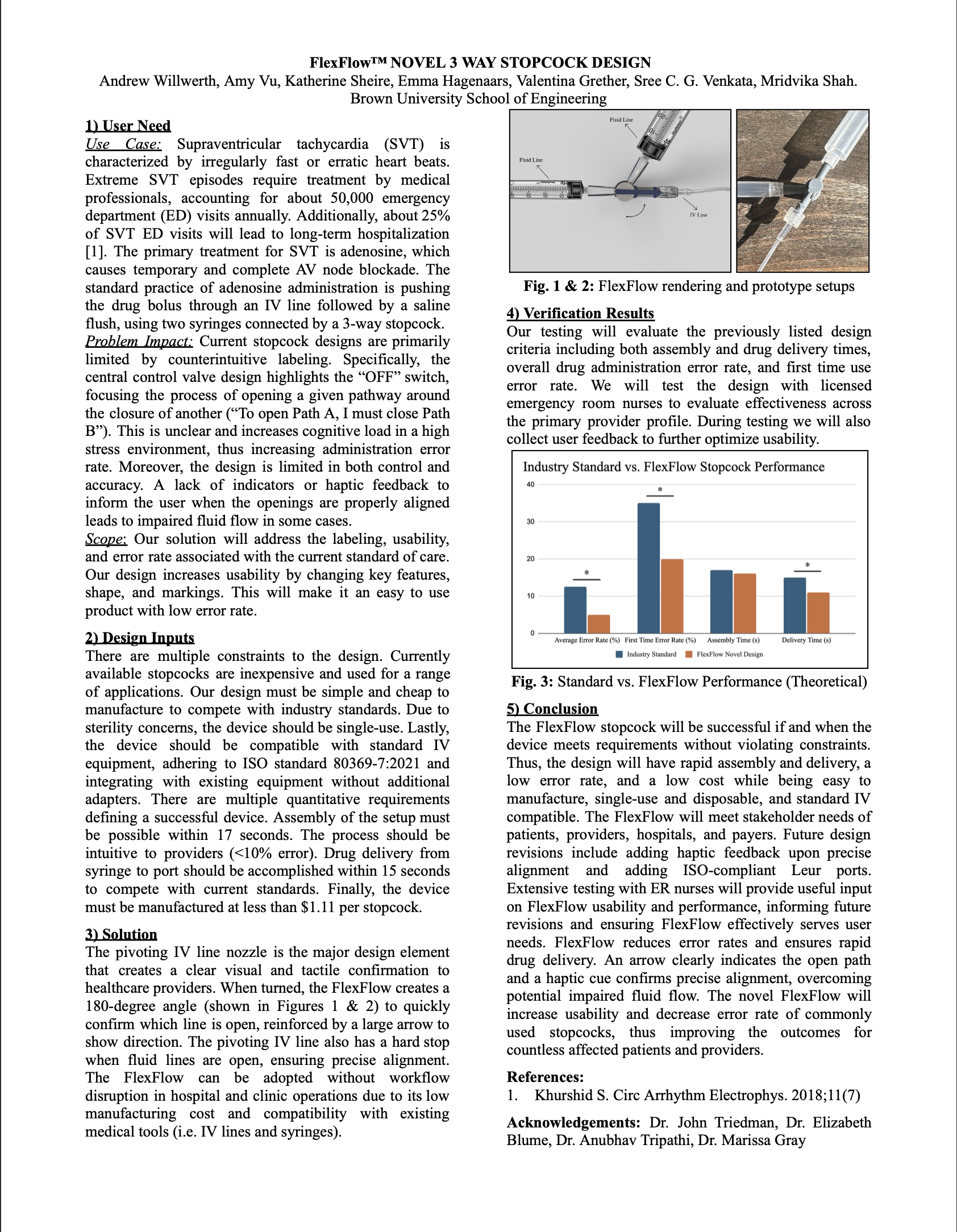

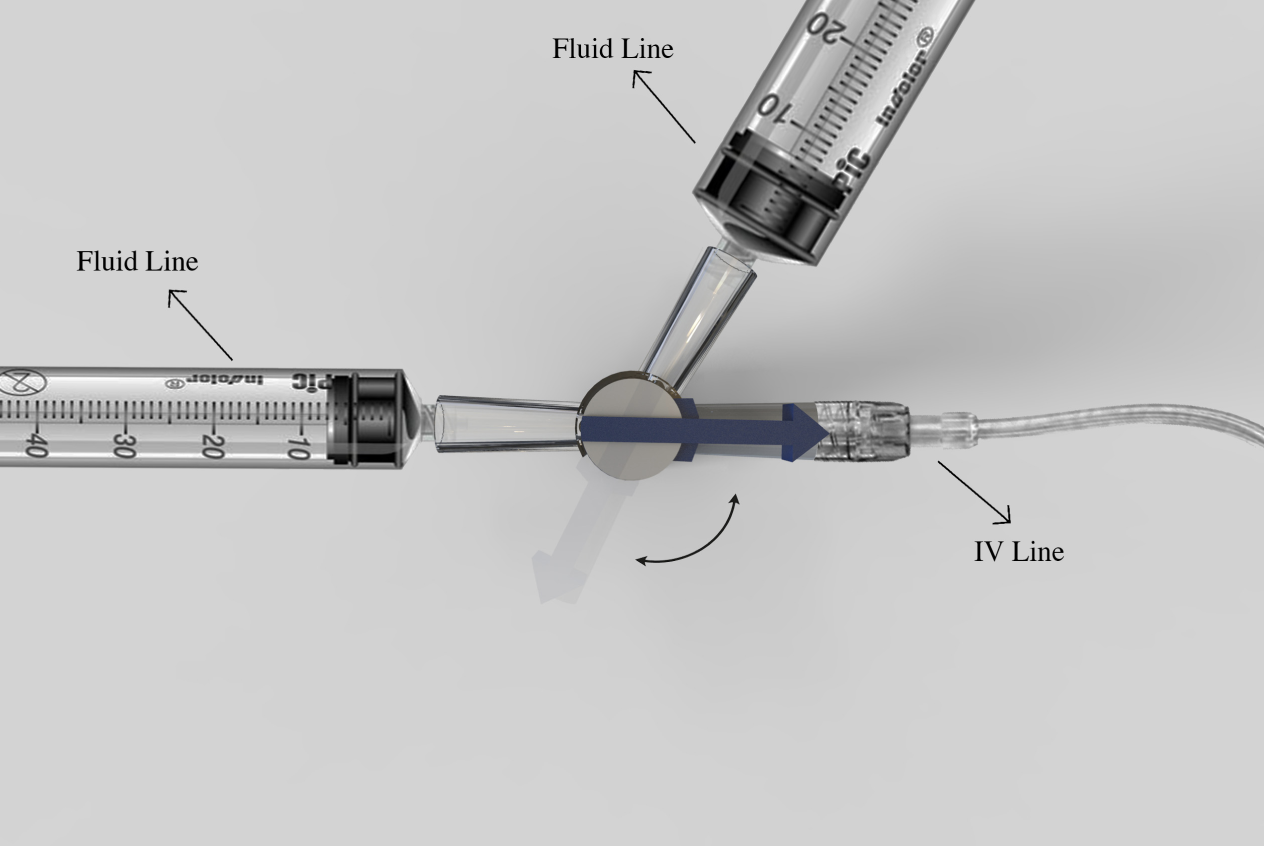

FlexFlow™ is a novel three-way stopcock redesigned to make IV line setup and drug delivery more intuitive and error-resistant in fast-paced clinical settings. Instead of a confusing central control valve, FlexFlow uses a pivoting IV line nozzle that physically aligns with the intended pathway, giving clear visual direction-of-flow cues plus a tactile "hard stop" for accurate positioning—supporting dual drug delivery, infusion, and blood sampling while staying compatible with existing equipment.

Challenge

How might we redesign the traditional three-way stopcock to create a more intuitive, efficient, and error-resistant solution for healthcare providers in high-pressure environments?

Product Features

Directional Arrow indicators

High-visibility arrows on the body of the device that clearly communicate direction of flow, so users can confirm the intended pathway in seconds without relying on memory or interpretation of confusing markings. Designed for quick, at-a-glance readability during fast-paced use.

Intuitive Hard stop

FlexFlow features a built-in "hard stop" at key positions that gives clear tactile confirmation when the flow path is correctly aligned, helping prevent over-rotation and accidental mispositioning.

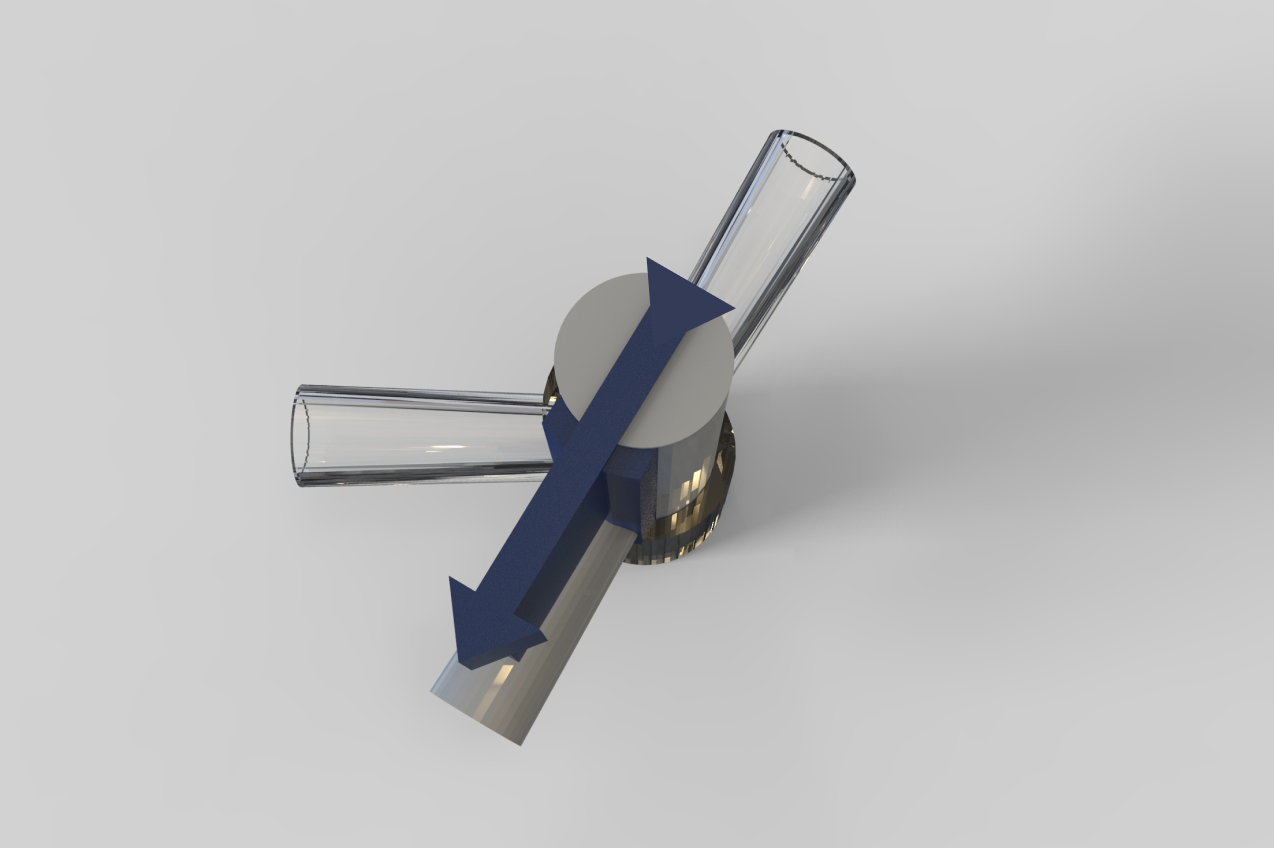

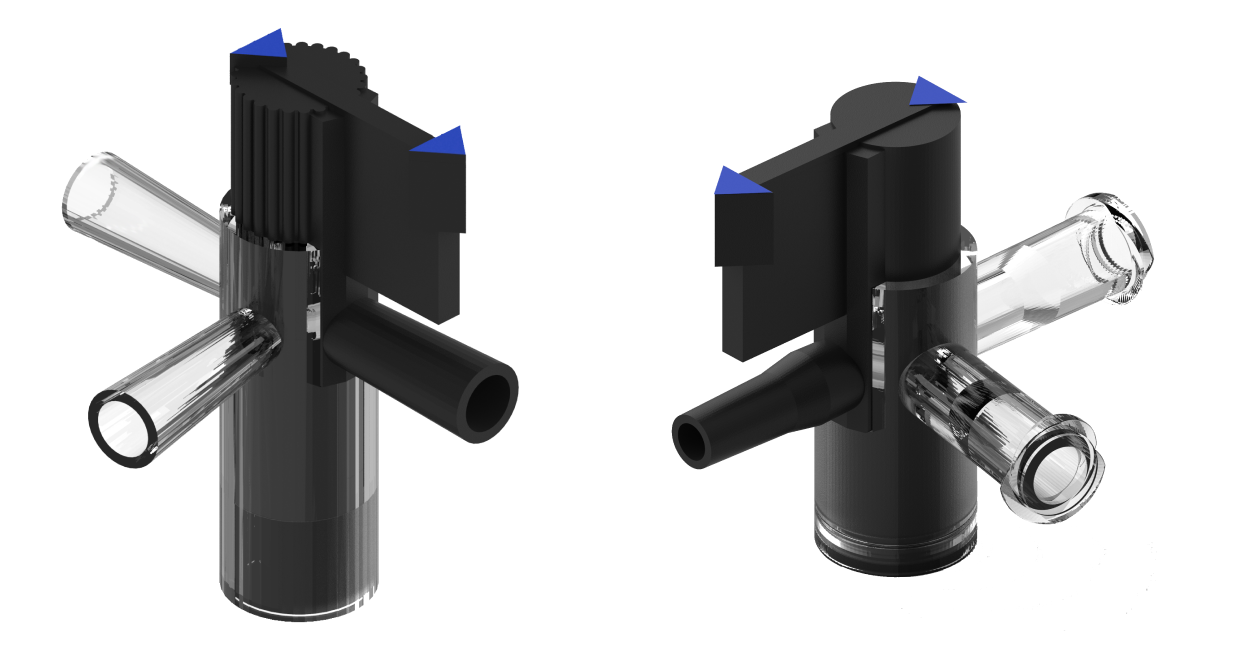

Pivoting Fluid Line

A rotatable fluid line that pivots to physically align with the selected pathway, making flow selection intuitive and visually legible at a glance due to 180 degree alignment.

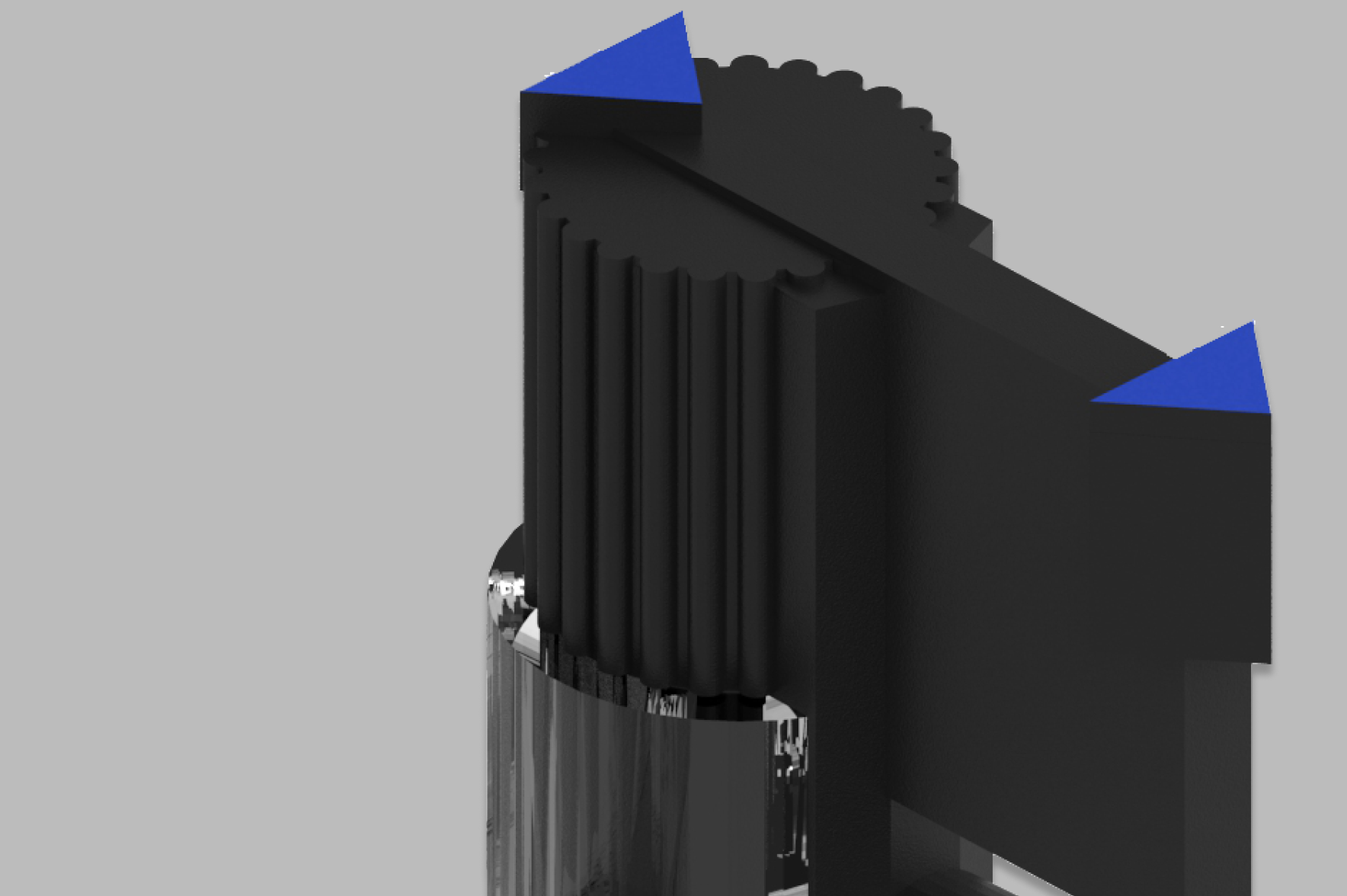

Grip

A textured, easy-to-hold surface designed to support quick, secure handling—especially with gloves—so users can rotate and position the component confidently without slipping during fast-paced use.

Team + Role

I served as the team's Industrial Designer, collaborating with teammates from Biomedical Engineering, Engineering, and Economics/Business backgrounds—where my responsibilities included design research and ideation, sketching and concept development, dimensional measuring and tolerance checks, CAD modeling, rapid prototyping (3D printing full-scale test models), iterative fit/function refinements, and final rendering/visual communication for presentations and reviews.

Process

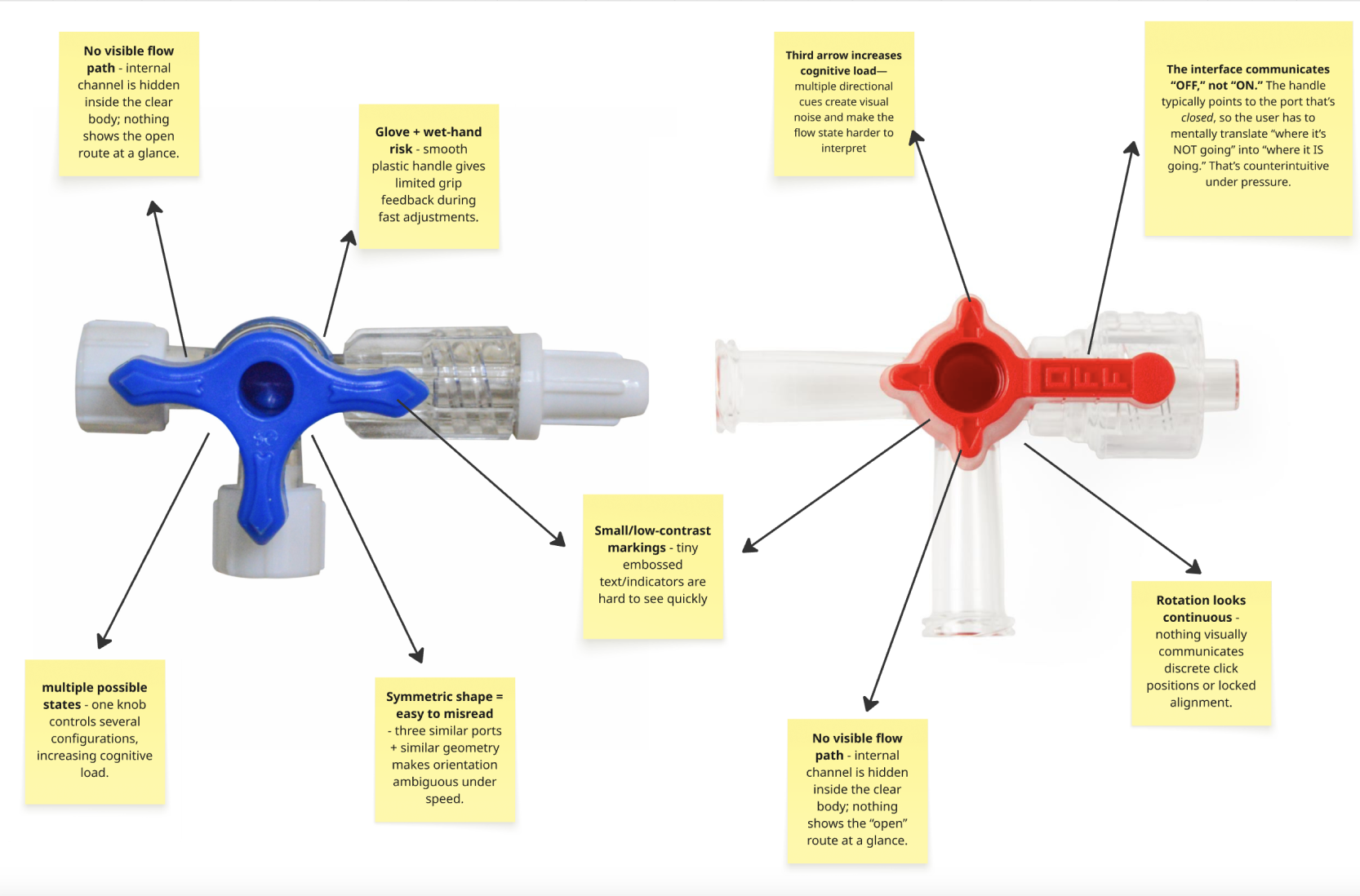

Usability Pain Points of existing 3-Way Stopcock

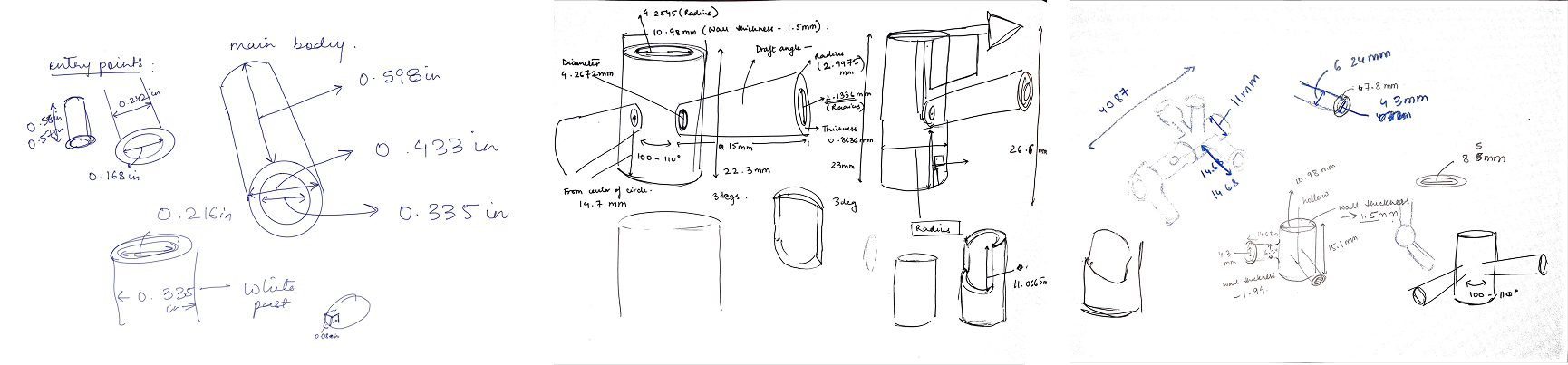

Dimensional Study + Early Mechanism Sketches

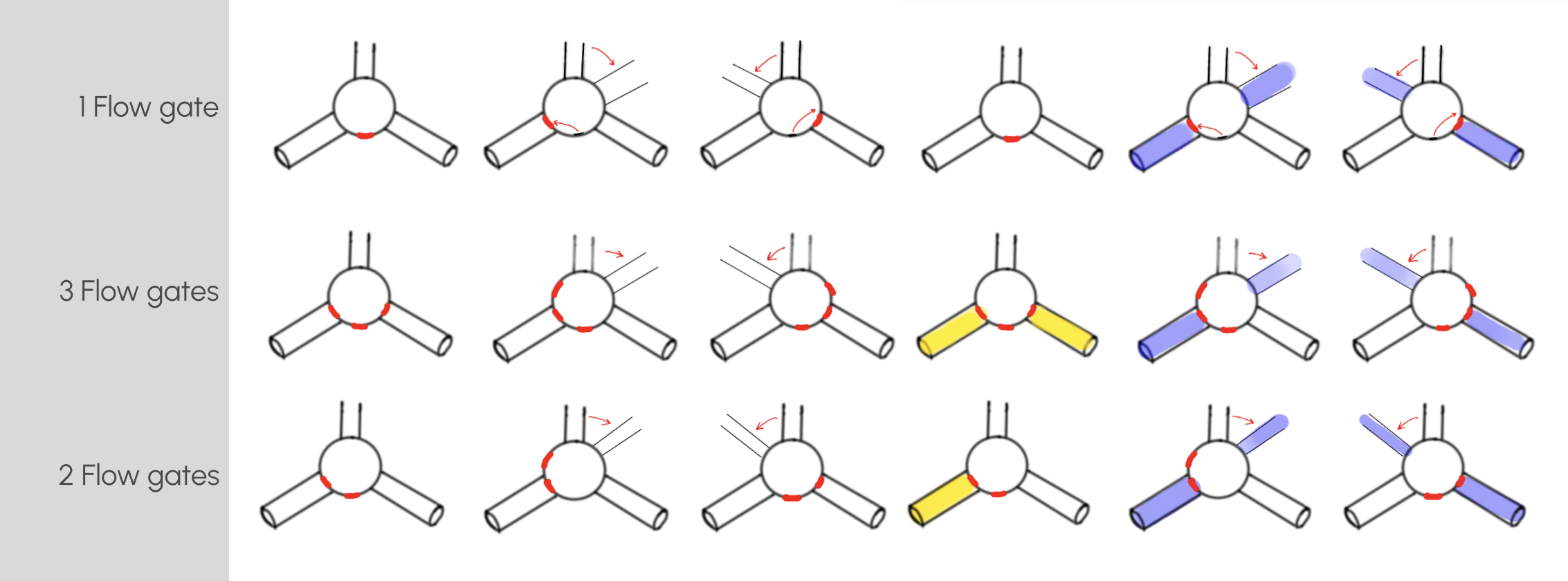

Exploring Hole Options for Flow (Soft-Angled Stopcock)

I explored multiple internal hole/port configurations for a wider, softer-angled stopcock—shifting the geometry from a harsh 90° to ~110°—to achieve clean 180° alignment between the active inlet and outlet. By testing different hole placements and angular offsets, I ensured each position fully opens the intended pathway (without partial closure), reduces misalignment risk, and keeps rotation intuitive and repeatable.

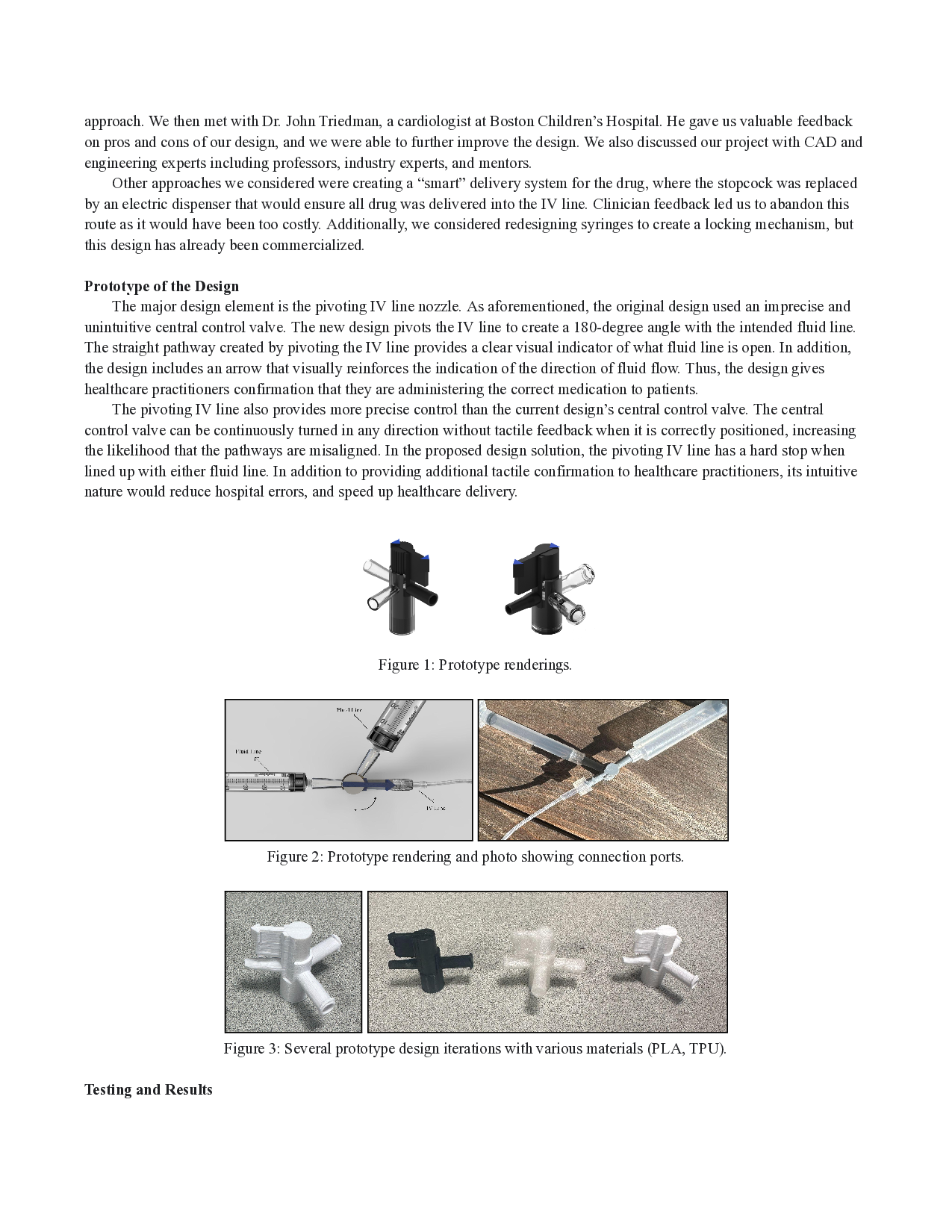

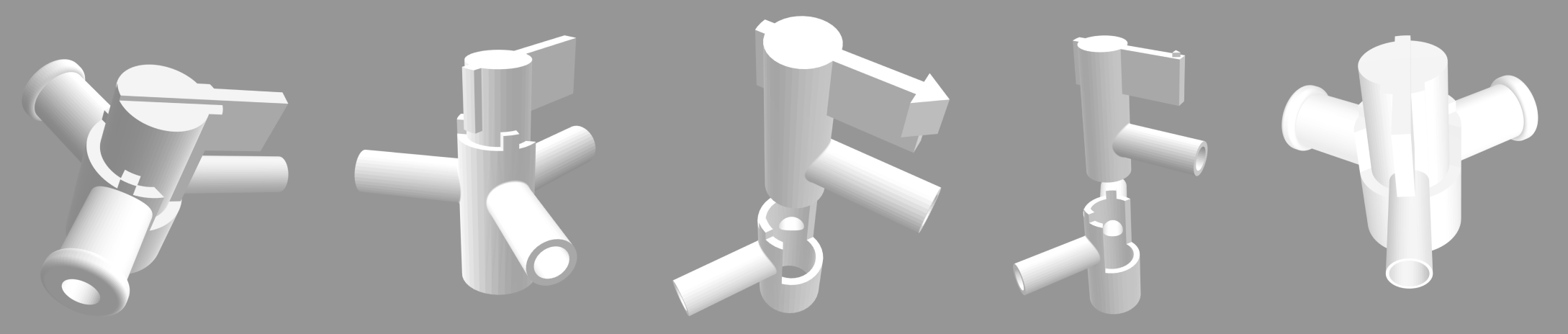

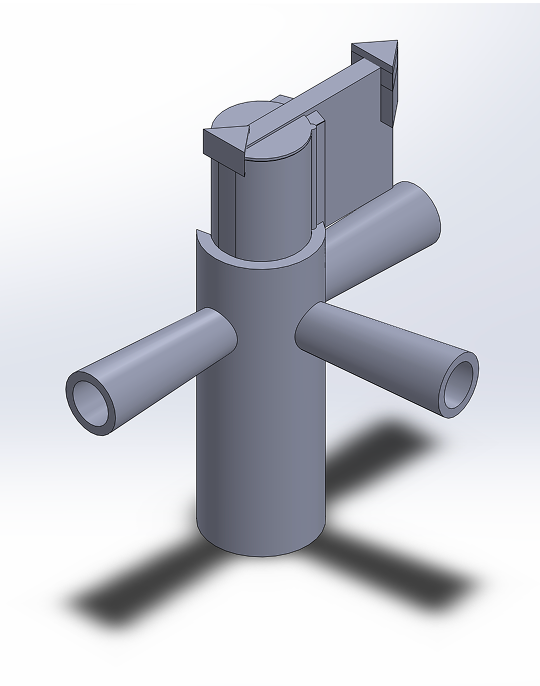

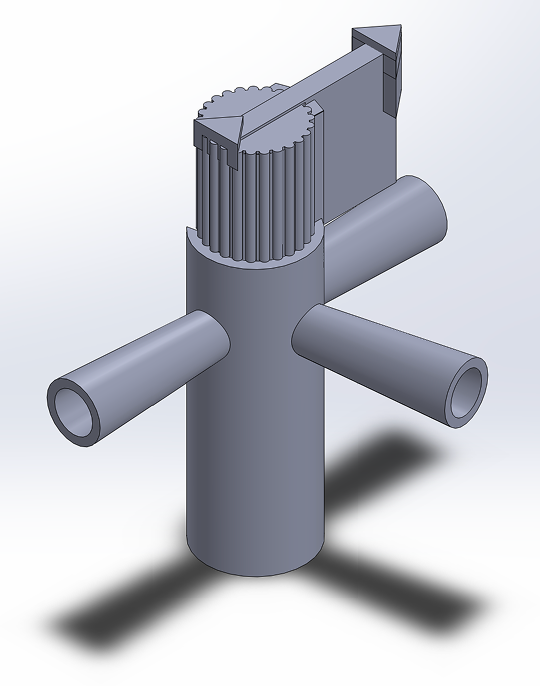

Prototyping using CAD

I used CAD to quickly iterate on geometry, tolerances, and interface details—tweaking clearances, stop angles, and part fit to ensure reliable alignment and smooth rotation without play or binding. Each revision balanced manufacturable fit with human factors, refining grip surfaces, visual cues, and tactile feedback so the mechanism felt intuitive and confident to operate

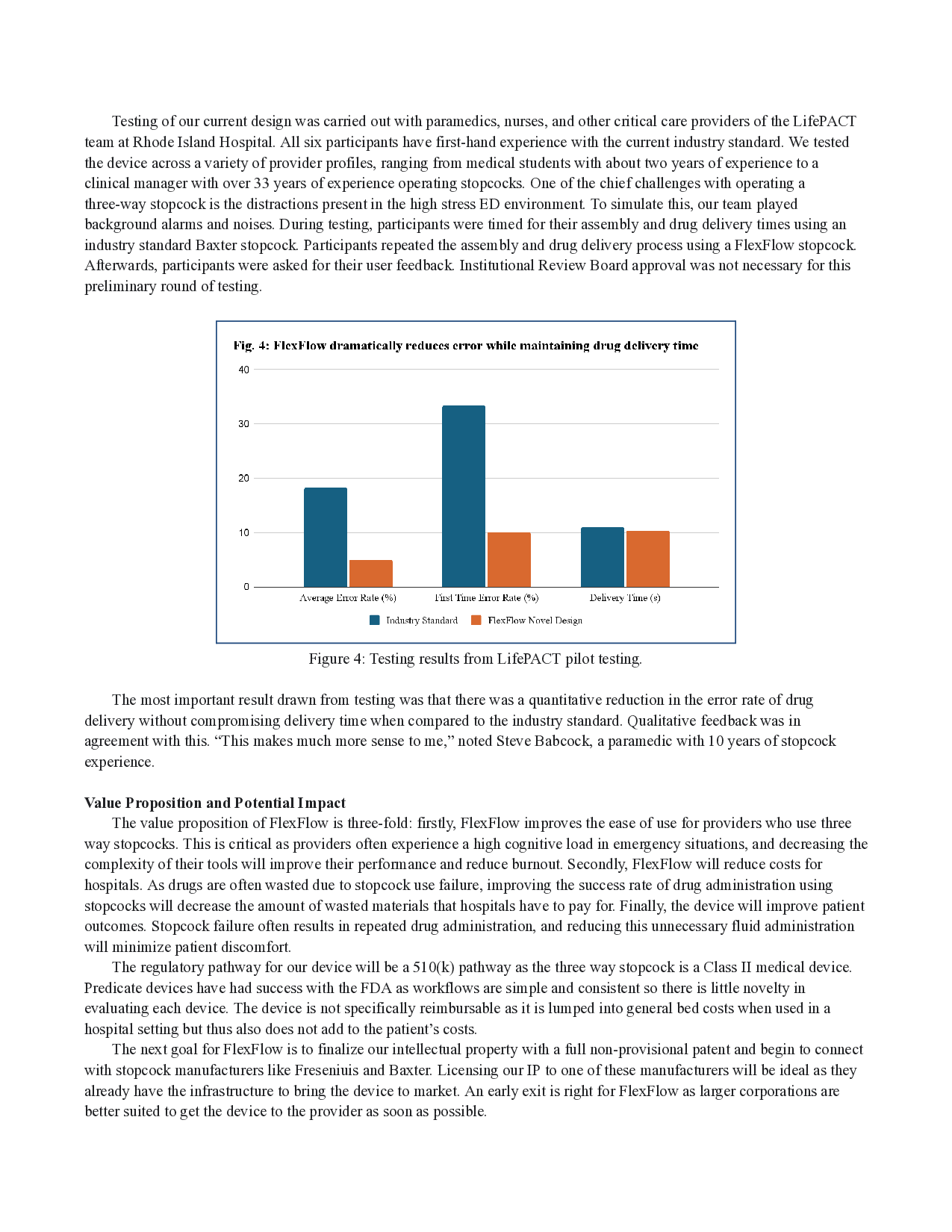

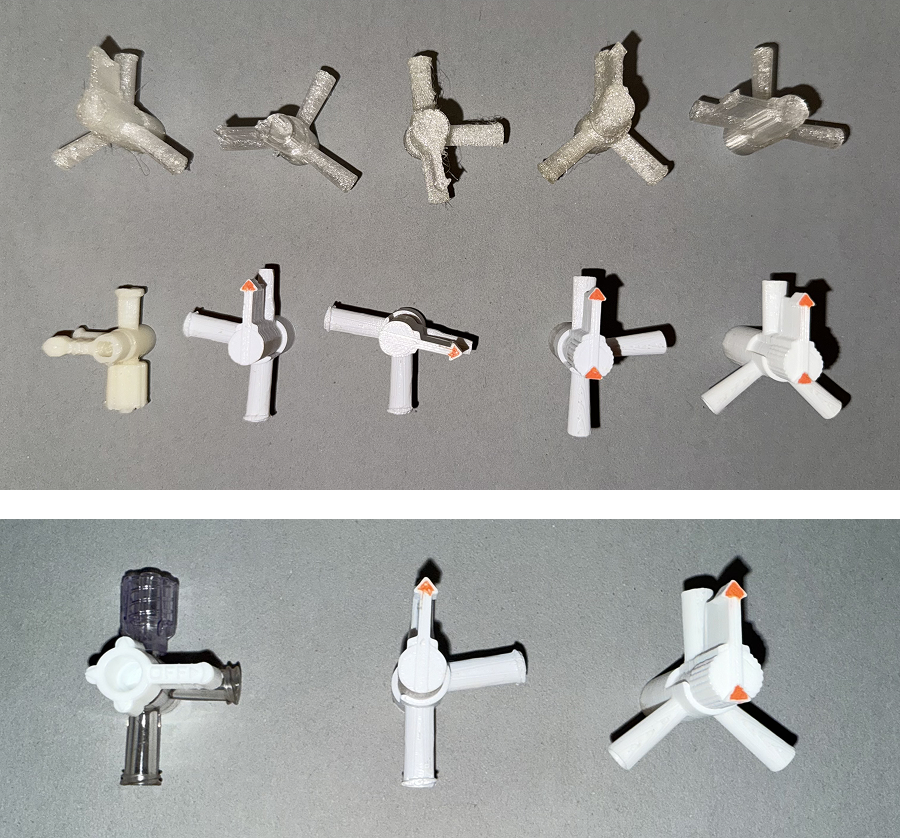

Physical Prototyping

I 3D-printed multiple stopcock iterations at scale to rapidly test form and interaction. Using PLA for quick, rigid geometry checks and TPU for flexible components, I explored variations in port angles, handle/grip profiles, and indicator placement. Each print helped validate usability factors—how confidently it could be held and rotated (even with gloves), how clearly flow states could be read, and how reliably parts aligned during operation—before refining the next CAD revision.

Testing

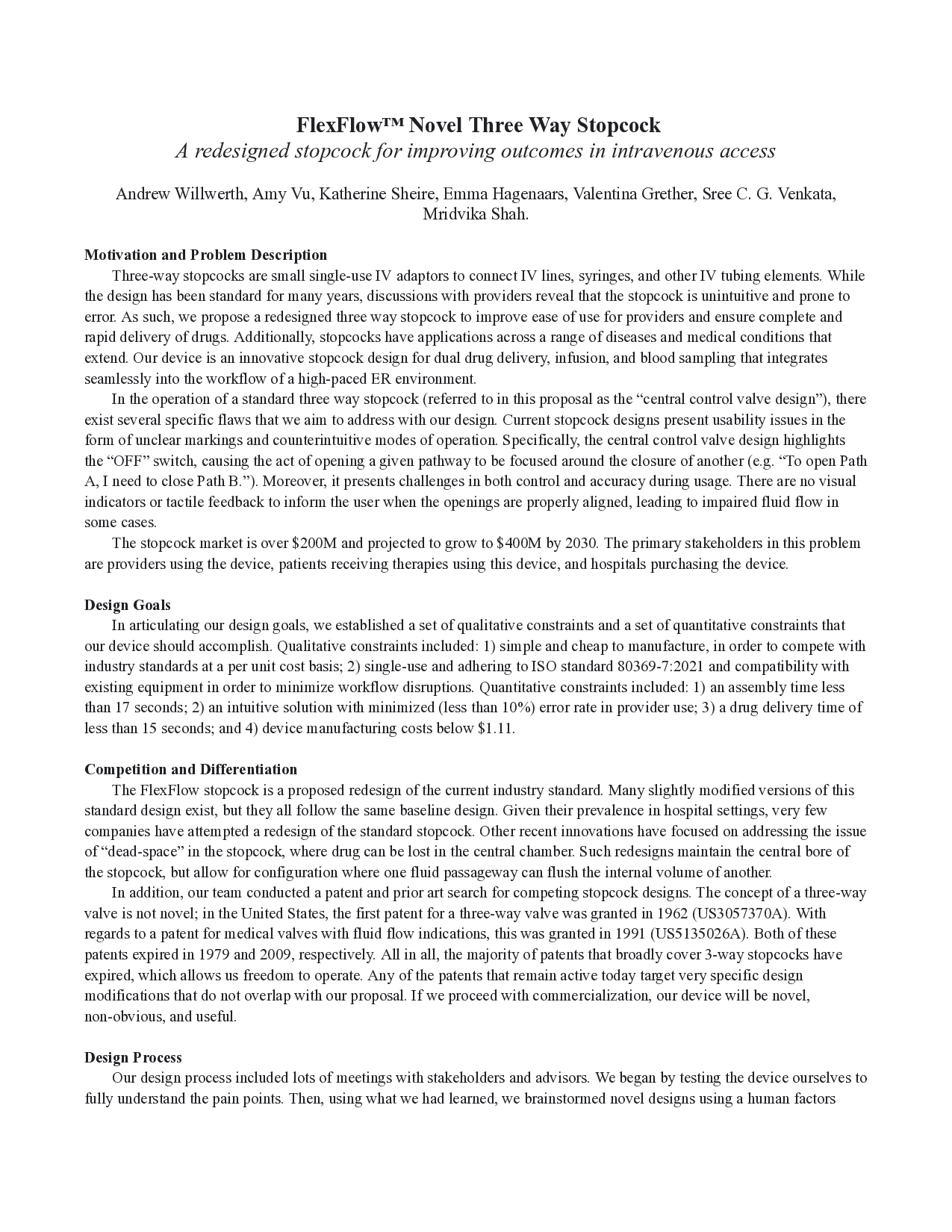

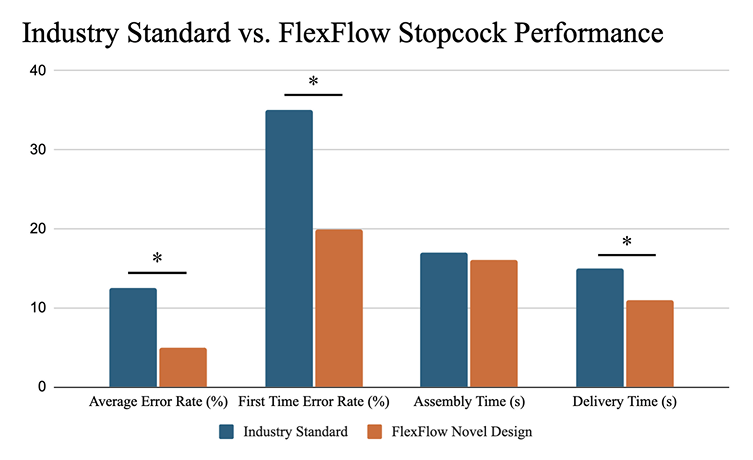

We evaluated FlexFlow with paramedics, nurses, and critical care providers from the LifePACT team at Rhode Island Hospital. To simulate real ED conditions, we played background alarms and noise, then timed assembly and drug delivery using an industry-standard Baxter stopcock versus FlexFlow, followed by user feedback. Results showed a quantitative reduction in drug-delivery errors without compromising delivery time, supported by clinician feedback ("This makes much more sense to me."). In parallel, I conducted iterative in-studio validation—running repeated water-based assemblies to check for leak points, sealing reliability, and alignment consistency across positions—using each round of leakage findings to refine fit, tolerances, and retention features.

Additional Information